ALUMVERDE TECHNOLOGY

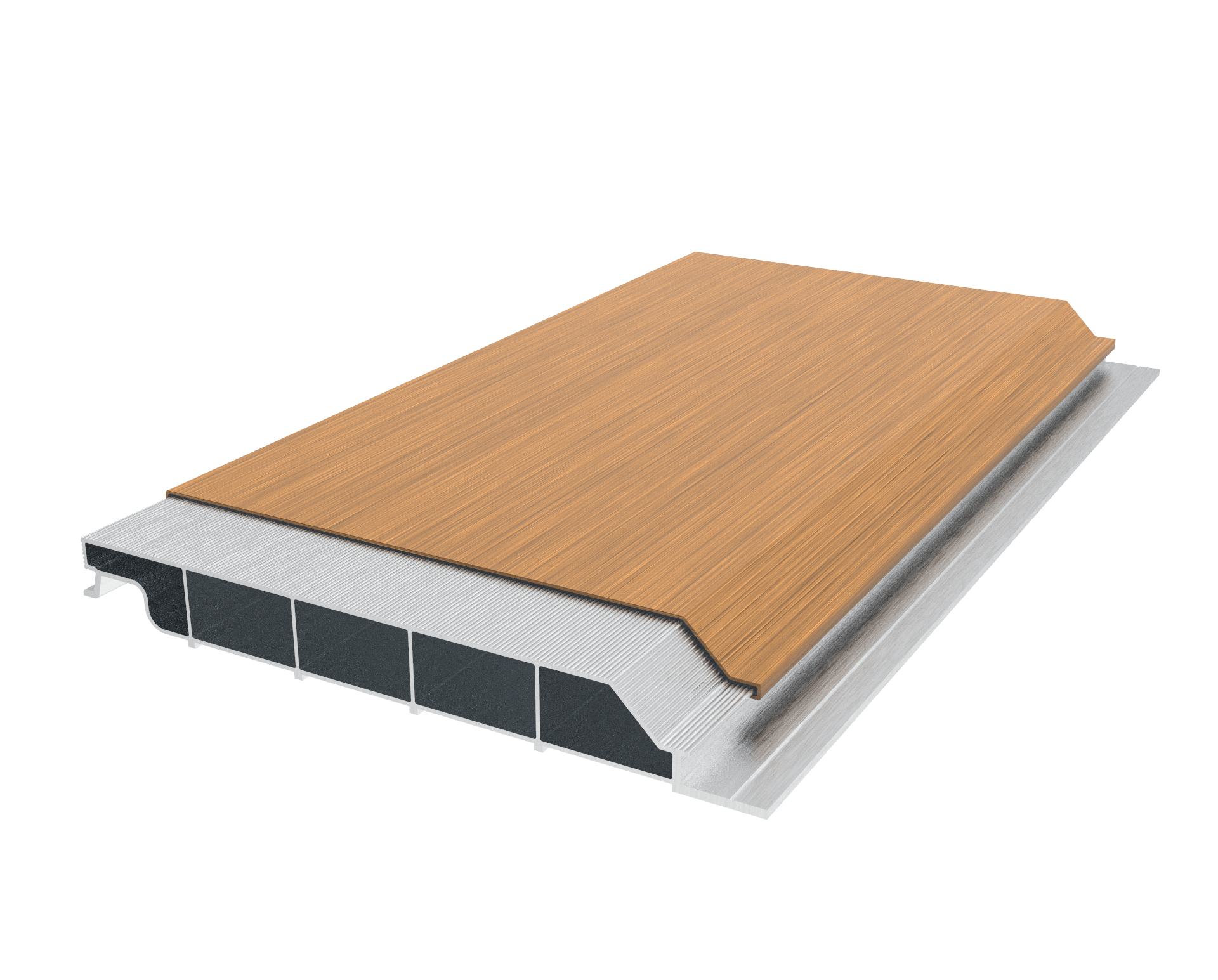

After 15 years of dedication to plastic and WPC materials, Mexytech has introduced Alumverde technology—a new and innovative series aimed at achieving the perfect balance between the authentic look of wood and the superior stability of aluminum materials. This development represents Mexytech’s continued pursuit of advanced, sustainable products that combine the natural beauty of wood with the lasting durability of synthetic solutions.

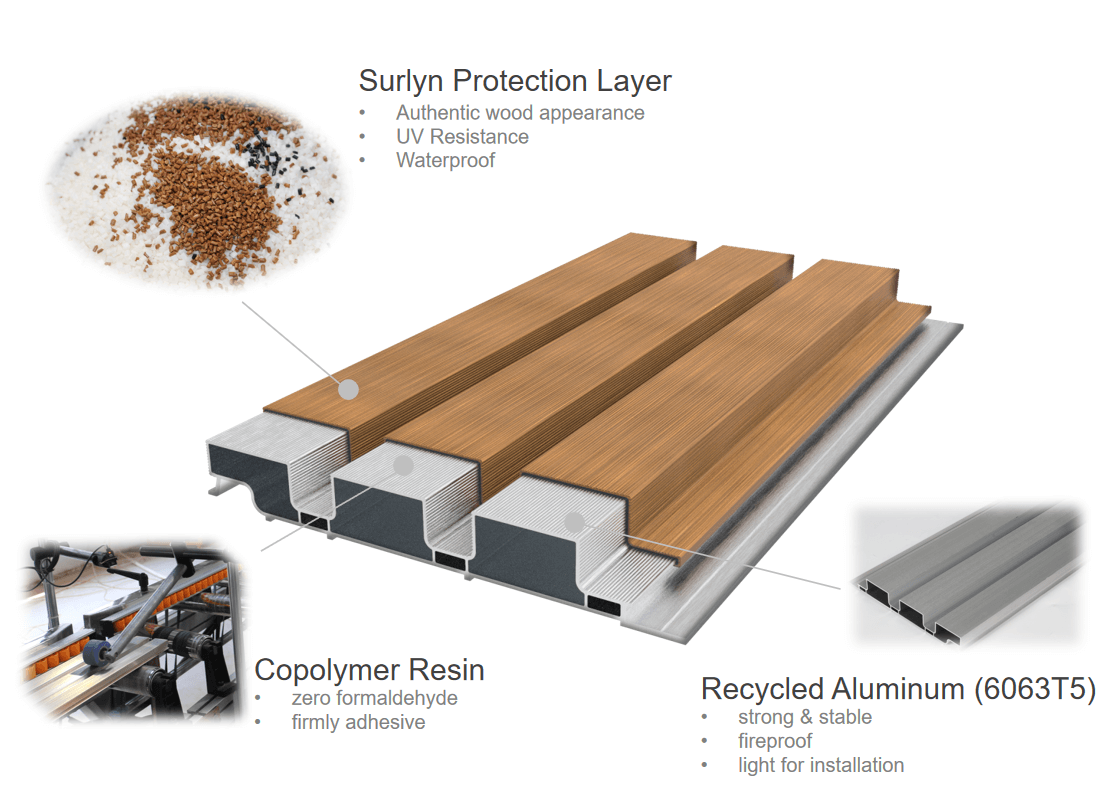

We made the protection layer with upgraded surlyn resin.

The attempt to combine traditional wood-plastic composite (WPC) with aluminum is not new. Classic WPC, with its slightly rough texture, offers a tactile experience reminiscent of real wood. However, Classic WPC has its limitations, particularly in UV protection and waterproofing, especially in extreme environments. Just as WPC evolved into co-extruded WPC (second-generation WPC) to address these issues, the same protective technology has now been applied to aluminum profiles.

By coating aluminum with Surlyn, the same material used in golf balls, the product gains not only a wood-like texture but also a wider range of color and surface variations. Additionally, this innovation significantly enhances the material’s performance, making it more stable, durable, and resistant to environmental stress.

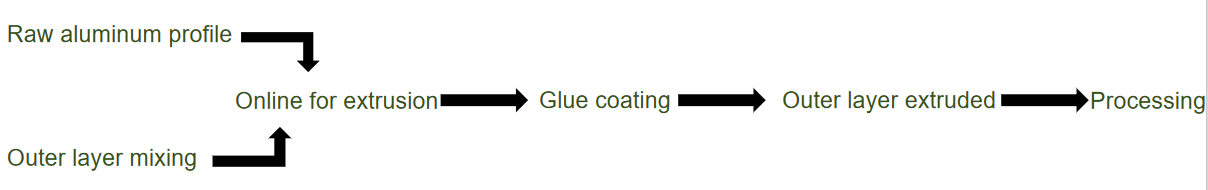

Process of Alumverde manufacturing

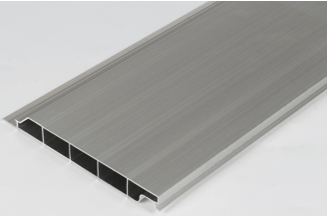

Extrusion of aluminum profile(6063-T5)

The first and most important step is the extrusion of aluminum. Since aluminum extrusion is a well-established technique, the focus is primarily on profile design. For our cladding and soffit applications, we prioritize strength and stability during real-world use, which is why we utilize a double-support structure

Outer layer mixing

The stunning color variation arises from even the smallest adjustments in the base plastic and color masterbatch. By sourcing Surlyn plastic from first-use recycled bottles,we maintain strict control over raw material quality while staying true to our eco-friendly vision.

Glue coating

Unlike co-extruded WPC, where wood-plastic composite and the outer layer are bonded primarily through high temperature and pressure, aluminum differs significantly from plastic in terms of material composition. As a result, combining the two requires a specialized hybrid technique that uses an intermediate copolymer resin to bond them together.

Protection layer extruded

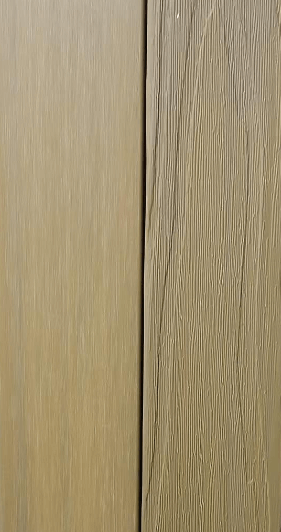

As the profile passes through the extrusion machine, a flowing mixing layer is formed and coated onto the aluminum surface. Following this stage, the Aluverde product achieves its distinctive, stylish appearance.

Texture Processing

This is a crucial final step that defines the product’s tactile feel and appearance. A deeper sanding creates a more textured, authentic touch, while lighter sanding results in a smoother, harder finish. By default, we achieve the perfect balance between the two.